Starblast Media Reliable Starblast Blasting Media

Por um escritor misterioso

Descrição

Starblast Blasting Media, a loose blend of coarse and fine staurolite sands. Weight: 50lbs. Sizes: Regular, Coarse, XL, Ultra, Biasill.

Starblast blasting abrasives are a loose blend of coarse and fine staurolite sands that are uniformly sized and have clean, rounded surfaces. Mined from Chemours mineral deposits in Northeast, Florida, the naturally occurring sands are washed to ensure freedom from dirt, dust, and ultrafines. Features and Benefits of Starblast Media The Starblast™ line of abrasive blasting material offers many benefits over alternative options for sandblasting, water jet cutting, and vapor blasting. These products are California Air Resources Board (CARB) certified and SSPC AB-1 certified. Both of these products contain very low free silica—Starblast™ abrasive media is guaranteed to contain <3% free silica (typically <2%), while Starblast™ XL is guaranteed to contain <1% free silica. Starblast™ XL is also QPL approved for MIL-A22262B-SH. Additional benefits of Starblast™ and Starblast™ XL abrasive media include: Greater blasting visibility due to minimal dust generation Lower labor costs through faster, more-efficient blasting Less material costs due to recyclability More uniform blasting pattern Sub-rounded to sub-angular grains result in less abrasive embedment Electrically nonconductive Chemours is producer of the product in Florida.

Starblast blasting abrasives are a loose blend of coarse and fine staurolite sands that are uniformly sized and have clean, rounded surfaces. Mined from Chemours mineral deposits in Northeast, Florida, the naturally occurring sands are washed to ensure freedom from dirt, dust, and ultrafines. Features and Benefits of Starblast Media The Starblast™ line of abrasive blasting material offers many benefits over alternative options for sandblasting, water jet cutting, and vapor blasting. These products are California Air Resources Board (CARB) certified and SSPC AB-1 certified. Both of these products contain very low free silica—Starblast™ abrasive media is guaranteed to contain <3% free silica (typically <2%), while Starblast™ XL is guaranteed to contain <1% free silica. Starblast™ XL is also QPL approved for MIL-A22262B-SH. Additional benefits of Starblast™ and Starblast™ XL abrasive media include: Greater blasting visibility due to minimal dust generation Lower labor costs through faster, more-efficient blasting Less material costs due to recyclability More uniform blasting pattern Sub-rounded to sub-angular grains result in less abrasive embedment Electrically nonconductive Chemours is producer of the product in Florida.

Blasting Blasting Tech Tips - 0 PDF, PDF, Fiberglass

Starblast Media Reliable Starblast Blasting Media

Starblast Blasting Abrasives, Finishing Systems

Starblast Blasting Abrasives, Finishing Systems

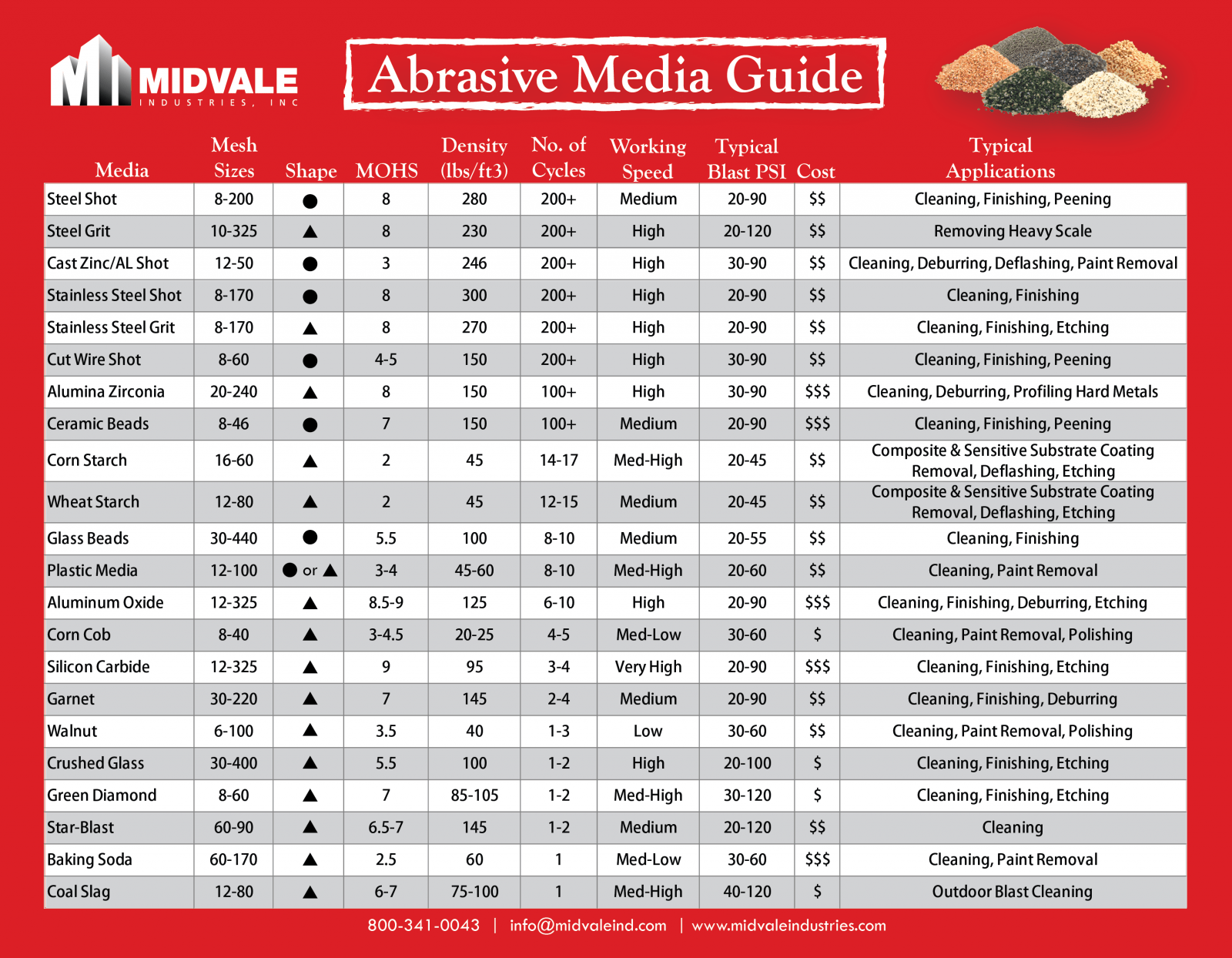

Abrasive Blasting Media Guide

Starblast sandblasting media is a blend of coarse and fine staurolite sands that are well-graded and have clean, rounded to sub-angular surfaces.

Starblast Sandblasting Media - Blastworks

Has anyone tried Starblast blasting abrasive?

Metal Casting Foundry, CAD and Pattern Making Facility, Sand Blasting. Margate Media Blasting Ltd., Kent.

Abrasive and Media Blasting Equipment

Sandblast Media Choosing The Right Sand Blaster Media

Sandblast Media Choosing The Right Sand Blaster Media

7 Things You Should Be Doing When Sandblasting - Midvale Industries

Starblast Media Reliable Starblast Blasting Media

de

por adulto (o preço varia de acordo com o tamanho do grupo)

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/24504649/cereza_forest.jpg)